In the industrial manufacturing world, efficiency, reliability, and cost-effectiveness are paramount. Industrial screw compressors have become a linchpin in the operations of many manufacturing plants due to their significant advantages over other types of compressors. From energy savings to continuous operation capabilities, these units offer a myriad of benefits that industrial operations cannot afford to overlook. Below, we delve into the specifics of how screw compressors can enhance manufacturing processes.

Exploring the Efficiency of Industrial Screw Compressors in Manufacturing

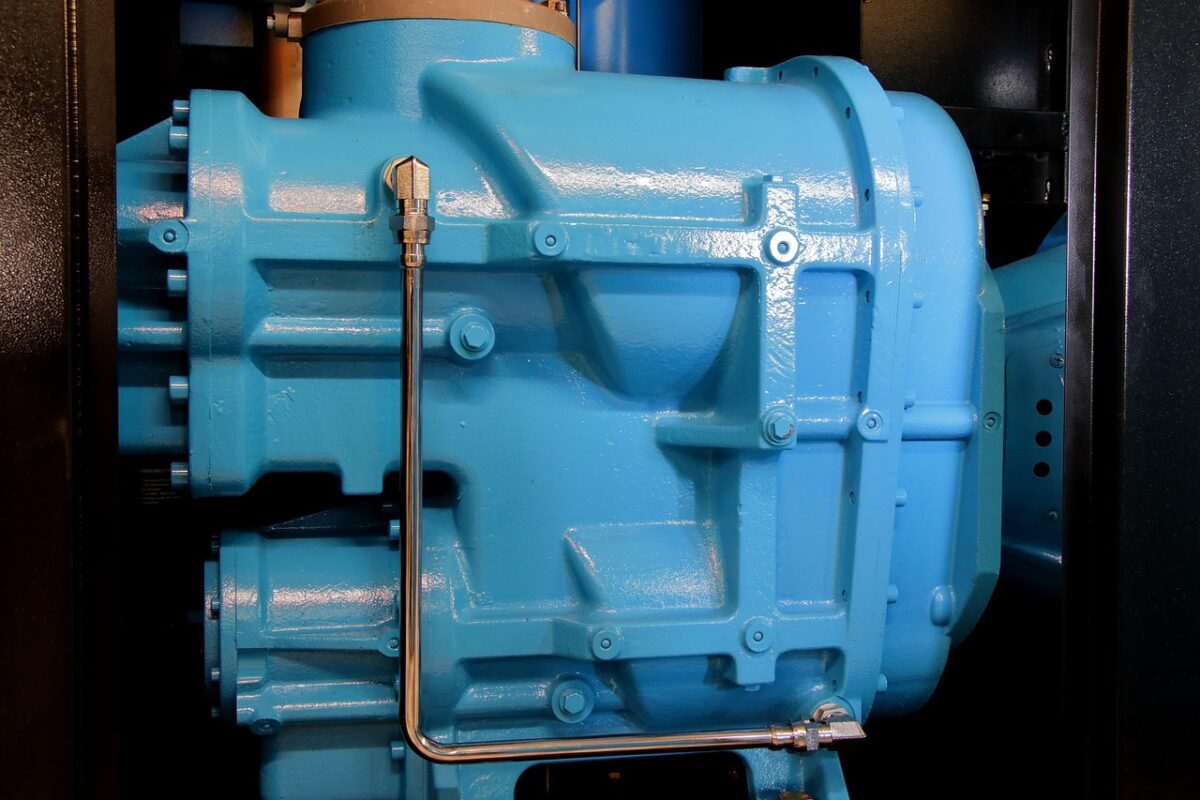

Industrial screw compressors are renowned for their ability to maintain consistent pressure and output, making them ideal for processes requiring a steady air supply. Their design minimizes energy loss by reducing the space between the rotating screws, thus enhancing compression efficiency. As a result, screw compressors often exhibit lower power consumption rates compared to other compressors in high-demand settings, which is integral for manufacturing plants looking to optimize their energy usage.

Moreover, the precision with which screw compressors operate ensures better process control. This is particularly valuable in scenarios where the quality of the product is directly affected by pressure-related variables. The accuracy provided by screw compressors minimizes defects and material waste, contributing to a higher yield and better product quality.

Another key advantage lies in the versatility of Industrial screw compressor units. Unlike other compressors that may only be suitable for specific tasks, screw compressors can be adapted to a broad range of applications. This adaptability allows them to support various stages of manufacturing, from powering pneumatic tools to contributing to product finishing techniques.

Industries have also noted the lower noise levels produced by screw compressors. Quieter operation creates a more pleasant work environment and reduces the need for extensive soundproofing measures. Altogether, the efficiency of screw compressors underlines their role as a competitive advantage in manufacturing processes.

Enhanced Durability and Reliability of Screw Compressors for Industrial Use

When it comes to industrial machinery, durability is non-negotiable. Screw compressors are built to withstand rigorous operations, often featuring robust designs and components engineered for longevity. Their ability to handle continuous, heavy-duty use reduces downtime due to equipment failure, which is critical in maintaining production timelines and reducing costly interruptions.

The design of screw compressors contributes to their reliability. With fewer moving parts than traditional piston compressors, there is less wear and tear over time. Consequently, the risk of mechanical failure diminishes, and the equipment experiences a prolonged operational life. This reliability further extends to their capability to operate at high temperatures without performance degradation, an essential aspect for harsh industrial environments.

With manufacturing processes often running around the clock, the consistent performance provided by screw compressors is invaluable. Regardless of fluctuating demand or ambient conditions, these units maintain their output, ensuring that production lines continue to function seamlessly. This reliability fosters trust in the equipment, which is crucial for manufacturers who cannot afford unexpected breakdowns.

Furthermore, the simplicity inherent in the screw compressor’s design facilitates easier diagnostics and repairs when issues do arise. With a simpler internal structure, technicians can quickly address maintenance needs, reducing the duration of interruptions and safeguarding the manufacturing process against prolonged periods of downtime.

The Role of Screw Compressors in Reducing Manufacturing Energy Costs

Energy consumption is a significant concern in manufacturing, often representing a substantial portion of operational costs. Screw compressors offer an eco-friendly solution with their inherently energy-efficient design. By matching supply with demand through variable speed drives, these compressors can minimize energy waste and provide substantial savings on electricity costs.

Due to their integrated cooling systems, screw compressors can also recover thermal energy. This heat can be redirected to fulfill other plant requirements, such as space heating or preheating materials for processing. These energy recovery systems can transform what was once a lost byproduct into a resourceful input, further cutting the overall energy expenses.

Choosing an appropriately sized screw compressor is equally critical for cost savings. An oversized compressor not only incurs unnecessary initial investment but also leads to additional energy expenditure over time. On the other hand, an accurately-sized unit will operate within its optimal parameters, conserving energy and functioning at peak performance.

When considering long-term costs, the energy efficiency of screw compressors simply cannot be overstated. By providing a consistent output with less energy input, these compressors effectively decrease the cost per unit of air or gas delivered. Over time, the savings generated from lower energy consumption become a considerable financial benefit for manufacturers.

The adoption of industrial screw compressors presents a wealth of benefits for manufacturing processes. Through efficiency gains, reliable operation, energy savings, continuous performance, and manageable maintenance, these units prove to be invaluable assets in the industrial sector. As manufacturing plants look for ways to streamline their operations and boost their bottom lines, the role of screw compressors remains unquestionably significant.